Concrete curbs and coves are required under CFIA Plant Construction Guidelines. Curbs protect your walls from damage, and coves provide a cleanable floor to wall junction.

Concrete curbs and coves are required under CFIA Plant Construction Guidelines. Curbs protect your walls from damage, and coves provide a cleanable floor to wall junction.

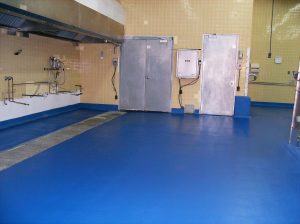

Epoxy and polyurethane finishes can be applied to floors, curbs, and coves to provide wear resistance and a non-slip surface.

Since its foundation in Switzerland in 1910, Sika has established itself as an international leader in construction chemicals with manufacturing facilities and distribution centres in more than 70 countries around the world. In keeping with Sika’s commitment to renewing and improving its products, systems and procedures on an ongoing basis, its manufacturing facilities around the world are ISO certified — to ensure that its high standards are consistently maintained. Sika is recognized as the undisputable benchmark for quality for a wide range of construction products, including:

- Concrete Restoration Products

- Grouts and Adhesives

- Structural Strengthening Systems

- Joint Sealants

- Moisture Protection Systems

- Surface Hardeners

- Industrial and Architectural Flooring

PurCem® 19N: Polyurethane concrete flooring, trowel-applied, slip-resistant

- Withstands thermal shock and thermal cycling

- Superior chemical-, impact and abrasion-resistance

- Medium- to heavy-duty applications

- 6 mm to 9 mm (1/4” to 3/8”) thickness

- Trowel application

- Slip-resistant finish

- Heat-resistant to 115˚C (240˚F)

- Can be applied over partially-cured concrete slabs (<10% moisture); full 28-day cure time is not necessary

- Minimal maintenance costs, superior life-cycle cost advantage over tile

- Integral cove base (using Sikafloor® 29N PurCem® detailing and coving mortar)

- CFIA-approved for use in food and beverage processing and handling areas.

Ideal for the following environments:

- Beverage processing plants and distilleries

- Chemical processing plants and refineries

- Containment areas

- Dairies and milk processing facilities

- Food processing facilities

- Freezers and coolers

- Fryer areas

- Institutional and commercial kitchens

- Heavy-duty manufacturing facilities

- Meat, fish and poultry packing plants

PurCem® 21N and 29N: Polyurethane concrete flooring self-levelling, smooth

- Withstands thermal shock and thermal cycling

- Superior chemical-, impactand abrasion-resistance

- Light- to medium-duty applications

- 4.5 mm to 6 mm (3/16” to 1/4”) thickness

- Self-levelling application

- Easy-to-clean, smooth finish

- Heat-resistant to 100˚C (212˚F)

- Can be applied over partially-cured concrete slabs (<10% moisture); full 28-day cure time is not necessary

- Minimal maintenance costs, superior life-cycle cost advantage over tile

- Integral cove base (using Sikafloor® 29N PurCem® detailing and coving mortar)

- CFIA-approved for use in food and beverage processing and handling areas

Ideal for the following environments:

- Bakeries

- Clean rooms

- Laboratories

- Medium-duty manufacturing facilities

- Powder production rooms

- Printing facilities (inks/dyes)

- Pulp and paper processing plants

- Warehouses